charpy impact test fracture energy|charpy impact test failure : broker In materials science, the Charpy impact test, also known as the Charpy V-notch test, is a standardized high strain rate test which determines the amount of energy absorbed by a material during fracture. Absorbed energy is a measure of the material's notch toughness. It is widely used in industry, since it is easy to prepare and conduct and results can be obtained quickly and cheaply. A disa. Trans Sjc - Assistir Os Melhores Videos Porno Grátis Sobre Trans Sjc. Site Adulto Publicando Milhares De Pornografia Online.

{plog:ftitle_list}

Marliéria, MG - Previsão do tempo para os próximos 15 dias .

charpy v notch impact test

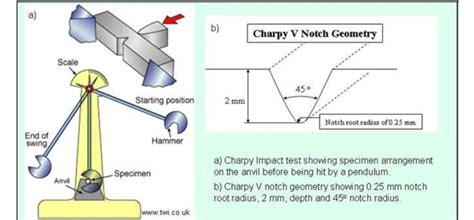

The Charpy impact test uses a simple yet effective formula to calculate the energy absorbed by the material during fracture. This energy measurement is key to determining the material's .The Charpy impact test, also known as the Charpy V-notch test, is a standardized high strain-rate test that determines the amount of energy absorbed by a material during fracture. This .In materials science, the Charpy impact test, also known as the Charpy V-notch test, is a standardized high strain rate test which determines the amount of energy absorbed by a material during fracture. Absorbed energy is a measure of the material's notch toughness. It is widely used in industry, since it is easy to prepare and conduct and results can be obtained quickly and cheaply. A disa. The Charpy impact test, introduced by Georges Augustin Albert Charpy (1865–1945) in 1901, is widely utilized for efficiently evaluating the toughness of materials. This .

Charpy impact testing is a method used to determine the toughness or impact resistance of materials, particularly metals. It measures the amount of energy absorbed by a material during fracture, providing valuable insight into its . The Charpy impact test, sometimes called a V-notch test, is a comparative-style test used to define a material’s impact strength by determining how much energy is required to fracture a pre-prepared and standardized .Brittleness is characterized by fracturing with low energy under impact. The fracture energy is proportional to the area under the tensile stress-strain curve and is called the toughness. .

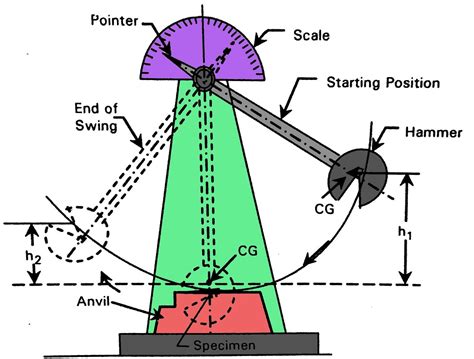

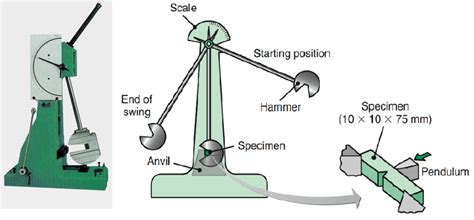

The Charpy impact test is used to find the amount of absorbed energy, meaning the amount of energy which was expended in fracturing the test piece. This energy can be calculated from the angle the hammer was initially lifted to, and .Charpy impact testing (CIT) is an ASTM standard fracture mechanics technique used to. moderately high strain r. standard E231, requiring a 55x10x10 mm beam with a 45°, 2 mm .Charpy impact testing is a method used to determine the toughness or impact resistance of materials, particularly metals. It measures the amount of energy absorbed by a material during fracture, providing valuable insight into its . In the Charpy impact test, this quantitative data is normally the energy absorbed during the fracture of the sample. The DBTT (Ductile-to-Brittle Transition Temperature) can also be estimated by testing the multiple .

Charpy impact testing was initially adopted for testing metals and then used in many early impact studies on FRP composites. The energy absorption and dissipation during the impact event as well as the failure mode can be tested. The specimen is usually in the form of a thick beam with or without a notch and is supported freely at two ends, as shown in Fig. 3 (a).The Charpy test is a pendulum-based test introduced by Georges Charpy and S. B. Russell. The test was valuable in understanding the material fracture in ships during world war II. The Charpy test consists of a pendulum and a hammer of known mass attached to it. The pendulum swings and hits the notched specimen to observe the energy transfer. On the other hand, due to simple operability of the impact test, the relation between impact toughness and fracture toughness has been investigated over the past decades. Rolfe-Novak-Barson [10], [11] established an empirical formula between Charpy impact energy and fracture toughness through analyzing numerous steels with different strength .

The Charpy impact specimens of each material are immersed in a bath for 10 minu tes to reach thermal equilibrium at five separate temperatures ranging from 110oF (-79oC) to 212-oF (100oC). The specimens are quickly transferred to the Charpy testing machine, fractured, and the impact energy is measured. AfterImpact energy. The energy required to fracture a standard specimen when the load is suddenly applied. Impact test. Measures the ability of a material to absorb a sudden application of a load without breaking. The Charpy test is a commonly used impact test. Lateral expansion. The lateral change in dimension of a Charpy impact specimen due to .

The Charpy impact test uses a simple yet effective formula to calculate the energy absorbed by the material during fracture. This energy measurement is key to determining the material's toughness. Although most Charpy impact testing machines are designed to directly display the energy in joules, understanding the underlying formula can give you .

material's capability in energy absorption in fracture. Standard testing procedure using the Charpy V-Notch (CVN) impact tests exists, i.e. the American Society of Testing Materials (ASTM) testing procedure E-23 [4], The results are plotted as CVN impact energy versus temperature as shown in Figure 1(a). In the plot, three

Materials – Charpy Pendulum Impact Test – Part 1: Test Method,7 consists of a physical part (direct verification) and an experimental part (indirect verification). The direct verification consists in the detailed evaluation of . During fracture, energy is consumed by initiating and propagating a crack through the specimen but also

The paper presents and analyzes the results of experimental tests performed on two non-alloy low carbon steels (1.1141 and 1.0122) in cases of their exposure to impact fracture energy and uniaxial high cyclic mechanical stress-controlled fatigue. The experimental results provide insight into the changes in the Charpy impact fracture energy of the V-notched test . The Charpy test is a high loading rate test that measures the energy absorbed during fracture, hence providing an indirect measure of impact toughness. For a Charpy machine to maintain an accurate absorbed energy scale, periodic verification with certified specimens is required.Mechanical testing of welds. Philippa Moore, Geoff Booth, in The Welding Engineer s Guide to Fracture and Fatigue, 2015. 9.5 Charpy testing. The Charpy test measures the energy absorbed when a notched bar of material is struck with a fixed-weight pendulum swung from a given height. The absorbed energy (in joules) is also referred to as the impact toughness of . How Charpy impact tests are performed. Specimen Preparation: A small, standardized specimen, usually a rectangular bar with a V-shaped notch machined on one side.The notch creates a stress concentration that promotes fracture when impacted. The test setup includes a pendulum hammer, a notched specimen holder, and a digital or analog .

Charpy impact testing was performed on the series of machined specimens with sub-size cross-section to obtain values of CVN impact energy. Fracture toughness test method according to ASTM E1820 .

charpy test impact energy

The Charpy impact test is performed to evaluate the resistance of the metal to breakage by flexural shock or impact load according to standard test method ASTM D6110. Fig 1: Charpy Test Apparatus This test determines the amount of . For comparison, conventional heat-treated steels were also fabricated. An instrumented Charpy impact test was performed, and the impact load (P) and deflection (u) during the test were recorded. . 2022. "Effect of .

The experimental results provide insight into the changes in the Charpy impact fracture energy of the V-notched test specimen that occur as a result of temperature changes. The experimental results also provide insight into the mechanical response of the tested materials to mechanical uniaxial high-cycle fatigue at room temperature in an air . In the domain where the fracture toughness is higher, the rise in fracture toughness with increasing Charpy impact energy is more pronounced. Detailed SEM examination of fractured compact tension (CT) and Charpy V-notch (CVN) specimens showed that the fracture at ambient temperature occurred almost exclusively by cleavage.quate to predict fracture toughness from Charpy impact energy. Fracture toughness and Charpy impact energy data for ASTM A723 steel were presented in graphical form by Underwood (ref 3). That data, along with addi- . "Impact Testing of Metels," ASTM STP 466, The American Society for Testing and Materials, Philadelphia, PA, 1970, pp. 281-302. There have been many empirical correlations developed over the years to determine fracture toughness from Charpy impact energy, most of them relating K Ic-values with CVN impact energy.A widely used relationship between fracture toughness and CVN energy derives from previous work of Barsom and Rolfe [13], [14], who developed a linear relationship .

Therefore, the Charpy impact test can be correlated with the mode I fracture test, which helps to prove that there is a certain quantitative relationship between the dynamic fracture toughness and the crack initiation energy, and also explains that it is rational to calculate the impact absorbed energy by SITs.The Charpy impact test is a standardized and widely adopted procedure. It measures a material’s resistance to sudden impact. This crucial assessment provides valuable insights into how well a material can absorb and withstand the energy generated during rapid . The Charpy impact test (CVN) is still the most widely used test for evaluating the absorbed energy and transition temperature of line-pipe steels because of its simple testing method and fewer .

The reference temperature for fracture transition (T0) can be obtained from Charpy impact testing following a correlation between Charpy impact energy (CV) and static fracture toughness, KIC [230 .According to current Charpy test standards (ASTM E23-12c and ISO 148-1:2009), absorbed energy (KV) results from partially fractured test specimens can be averaged with the results from fully fractured specimens. However, most researchers agree that if a specimen does not fully fracture at the end of a Charpy test, a significant The purpose of this study was to evaluate fracture resistance in AISI 304. The J-R curve was constructed from data, which resulted from an impact test by Charpy Impact machine equipped with high .

urethane leak test seals

DDTank 337-br. 480,607 likes · 12 talking about this. Somos o DDTank Oficial no Brasil. Confira a nossa página: http://www.337.com/pt/ddtank/

charpy impact test fracture energy|charpy impact test failure